AdBlue problem on Sandvik LH loaders

Sandvik, uses for many machines, latest generation Volvo Penta engines complying with the Tier 4F standard, equipped with an AdBlue SCR system. This can be set to default and reduce the use of the vehicle. Indeed, the limited engine power and torque prevent the loaders from operating properly. Our solutions will allow you to troubleshoot your system in minutes with our Continental ACM block virtualization module.

Sandvik, uses for many machines, latest generation Volvo Penta engines complying with the Tier 4F standard, equipped with an AdBlue SCR system. This can be set to default and reduce the use of the vehicle. Indeed, the limited engine power and torque prevent the loaders from operating properly. Our solutions will allow you to troubleshoot your system in minutes with our Continental ACM block virtualization module.

AdBlue troubleshooting on various Sandvik loaders.

AdBlue troubleshooting on various Sandvik loaders.

Our virtualization boxes make it possible to neutralize AdBlue defects and therefore to find a functional machine in a short period of time. Now let’s take a look at the supported loaders.

Impacted engines and vehicles for which we have the solutions

Engines under Tier 4F and earlier

Adblue removal on Sandvik LH621i – TAD1374VE – D13J Volvo Penta – 375kW

Adblue removal on Sandvik LH517i – TAD1372VE – D13J Volvo Penta – 315kW

Adblue removal on Sandvik LH514 – TAD1171VE – D13J Volvo Penta – 265kW

Adblue removal on Sandvik LH410 – TAD872VE – D8J Volvo Penta – 210kW

Adblue removal on Sandvik LH307 – TAD572VE – D5J Volvo Penta – 160kW

Emulation Module Key Features and Functionality

The Sandvik vehicle will again have all the characteristics of intervention, Speed and efficiency of movement

No or No more SCR faults

No more torque reduction and power loss on your Sandvik loader

New technology ! Plug & Play connector, Replaces the original ACM ECU.

HCDEA™ – HamCom Dynamic Emulation algorithm

HCDMA™ – HamCom Direct Memory Access algorithm

Reversibility, at any time you can return your vehicle to the original configuration once the repair is complete

Replacement of the box in less than 30min

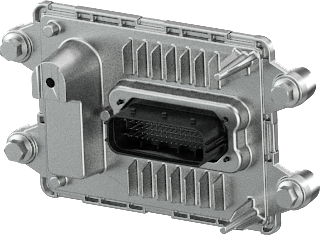

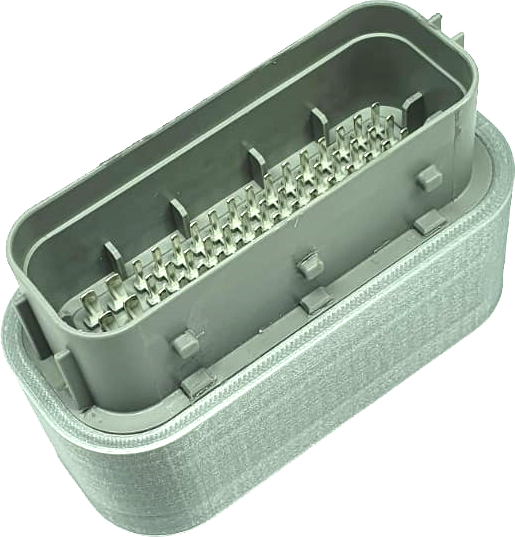

Proud of our ACM (After Treatment Control Module) data virtualization solution, we have opted for an ease of installation that allows even unqualified personnel to want to troubleshoot themselves. The assembly is simple and the result is 100% effective. The box is molded with the original connector of the vehicle, as you can see in the photos below the electronic part is stored in the top of the box and certified Iso 9001 responding to operating temperatures between -20° and +60°C. We come to connect the original harness of the vehicle in a ‘plug-and-play’ way.

Common Adblue faults and known symptoms on Sandvik loaders

Faults encountered on the different vehicles

Faults encountered on the different vehicles

In the majority of cases, AdBlue faults correspond to a physical problem present in the system. A defective pump, seized AdBlue injector or its defective electronic part, NOx sensor, crystallization problem or clogged DPF, etc…

For a more in-depth diagnosis

We have Volvo Penta/CE & Trucks diagnostic equipment in order to diagnose the origin of the problem more precisely if you wish, but also in order to be able to erase persistent faults. The diagnostic connector, depending on the machine, may be Volvo Penta proprietary or meet the OBD2 standard. If you are located abroad we can send you our diagnostic equipment and take control remotely once connected to the vehicle.

We have Volvo Penta/CE & Trucks diagnostic equipment in order to diagnose the origin of the problem more precisely if you wish, but also in order to be able to erase persistent faults. The diagnostic connector, depending on the machine, may be Volvo Penta proprietary or meet the OBD2 standard. If you are located abroad we can send you our diagnostic equipment and take control remotely once connected to the vehicle.