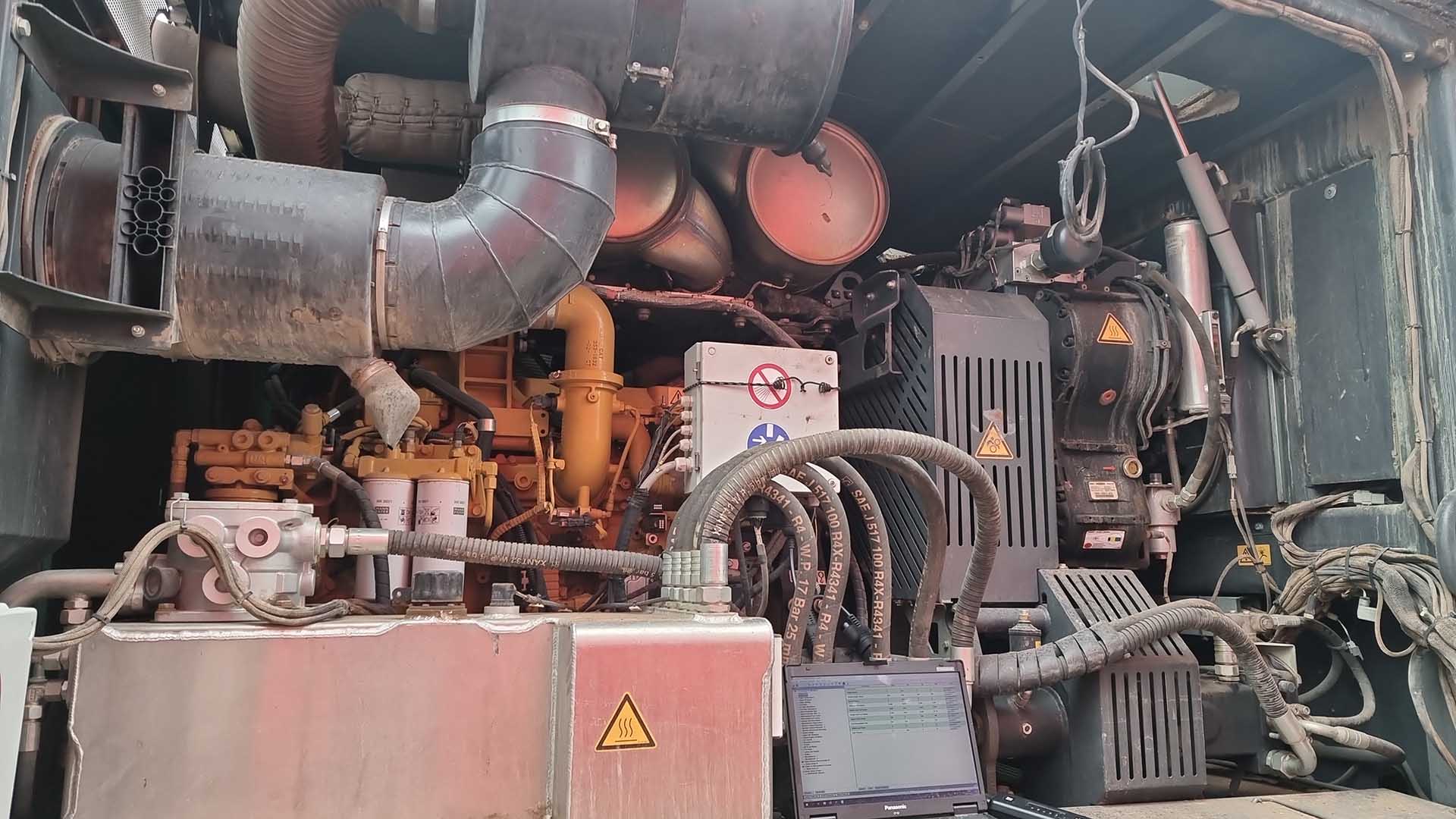

Adblue and FAP Komptech Crambo 5200 problem codes and faults

Definitive elimination of Adblue and DPF on Komptech Crambo 5200

If you own a Komptech Crambo 5200 chipper with the Caterpillar C13 engine, you may experience some problems. Mainly the concerns concern the DPF (particle filter) and Adblue (SCR) device. We give you more information on how to permanently resolve the problem as well as better visibility on the fault codes present.

The various codes such as 3714-31 indicate that regeneration is not possible due to the locking of the machine parameters. The following fault codes 3719-0 and 3719-16 show that the level of soot present in the DPF is high. Under the Tier 4F standard (inducement severity level) the level of severity includes different thresholds. Here the second ‘moderate severity’ threshold already prevents the machine from operating in optimal conditions, then the level 3 Severity blocks any probability of getting out of it without advanced or costly intervention. We also see that the ash content is also too high. In addition to the defects present in the filtration of fine particles, we have an SCR problem (4077-16).

How to get away with all these codes?

In itself there are not 2000 ways. Either you bring in CAT, which will change a large part of the machine’s anti-pollution components and relieve you of a good ten thousand euros, or you take the bull by the horns and delete the system permanently. The solution of removing the FAP and the SCR system is possible via our software, and programs specially developed for this operation. Theoretically, this operation is reserved when the machines go for export (legally it is forbidden in Europe to override the anti-pollution devices). It is reserved for Africa or the Middle East.

The success rate of the operation

Our team of engineers specializes in creating custom programs to remove emission control systems from a variety of equipment. The operation is always a success and above all allows to divide by 2 or 3 the bill.

Removing the particle filter requires the physical intervention of your team of technicians in order to empty it. The ceramic must be removed to allow the exhaust gases to circulate freely. In our case, we had a present soot rate of around 120%… which is enormous and requires immediate intervention.

No more defects after completion of the operation

The faults concerning the Adblue FAP and EGR system are now erased, the LIMP mode (Inducement reduction) is deactivated and the machine therefore regains all of its power.

Possible operations on the entire Caterpillar range

Our know-how allows us to work on all Cat machines, all engines and computers combined. You can find the summary and the feasibility of CAT machines on our explanatory page as well as all our operations already carried out here.