How to fix adblue problems on CAT 315F excavator, definitely.

Description of the symptoms and faults present

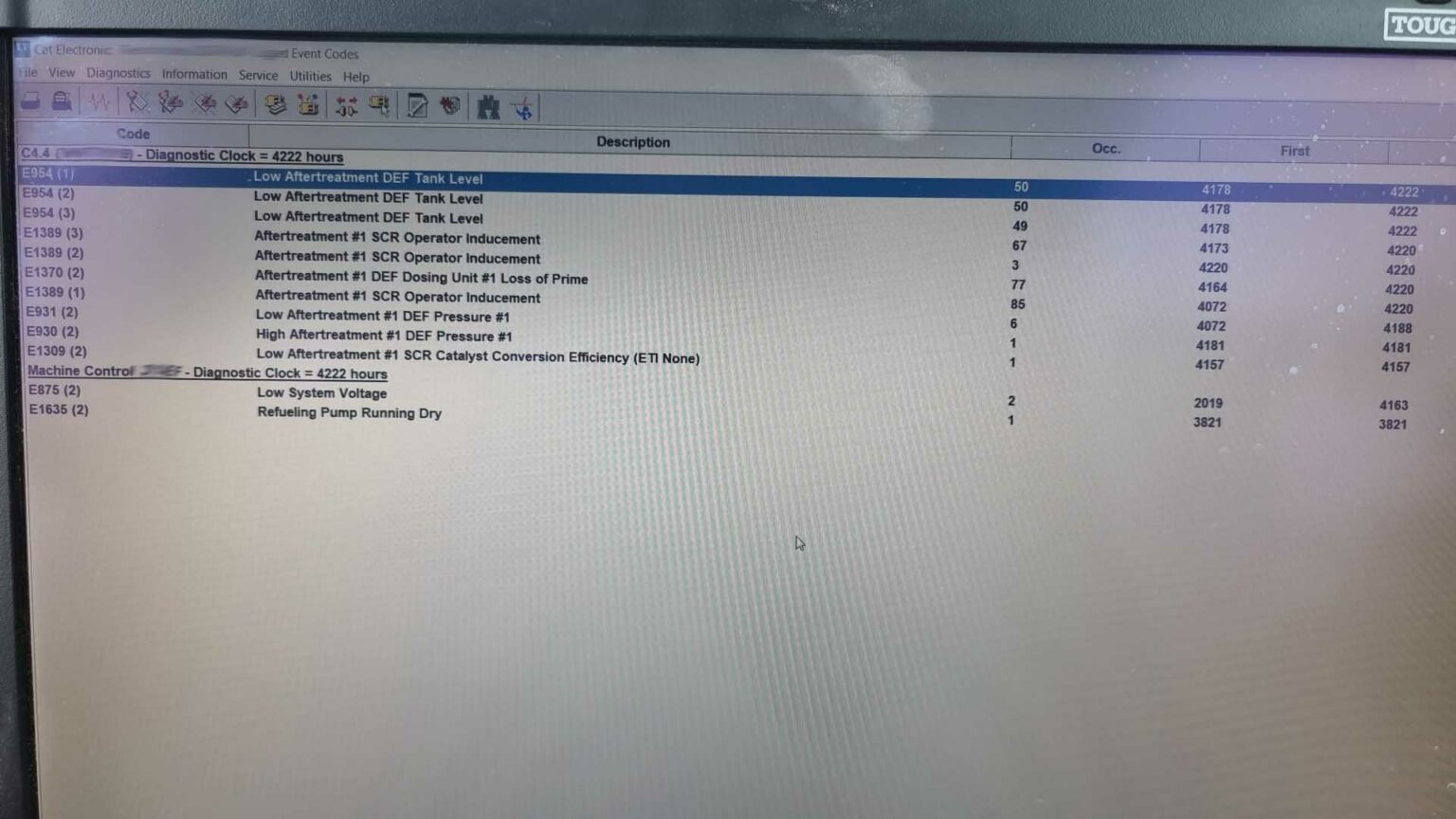

To solve adblue problems on CAT 315F excavator: The machine shows signs of impaired performance, such as repetitive power loss during use. These power losses may be accompanied by error messages displayed on the dashboard, indicating problems with the AdBlue emission reduction system. Diagnosing the cause of these symptoms is critical to maintaining optimum machine performance and avoiding potential failures. It is recommended to check the error codes related to the Adblue system

Overall description of the faults present:

E954: Low Aftertreatment DEF Tank: Lack of emission reduction fluid in the tank causes Diesel Particulate Filter (DPF) regeneration to be interrupted and the efficiency of the SCR system to decrease.

E1389: After treatment SCR Operator inducement: The defect of the SCR operator inducement causes a decrease in system performance. SCR (Selective Catalytic Reduction) is a system used to reduce nitrogen oxide (NOx) emissions in diesel engines. The inducement SCR operator refers to an error message that indicates that there is a problem with the SCR control system. It is often linked to problems with pressure, temperature, emission reduction fluid (AdBlue) flow, or faulty components in the SCR system. It may also be related to a lack of emission reduction fluid in the tank.

E1370: Aftertreatmet Def dosing Unit Loss of prime: Emissions reduction fluid dosing unit problem causes SCR system efficiency reduction.

E931 and E930: Low/High Aftertreatment Def Pressure: Emissions reduction fluid pressure issue causes SCR system efficiency to decrease.

E1309: Low Aftertreatment SCR Catalyst conversion Efficiency (ET) None: The SCR system catalytic conversion efficiency issue results in a loss of overall machine performance.

Consequences on the current construction site and emergency solution

The faults mentioned in the error codes can have a significant impact on the performance of the machine. Thus, repetitive power losses, interrupted Diesel Particulate Filter (DPF) regeneration, and SCR system pressure and temperature issues can all cause delays and reduced productivity on the job site. Therefore, these faults can cause machine breakdowns and require costly repairs, resulting in loss of money for the company. In addition, it is important to quickly diagnose and resolve these problems to minimize the impact on machine performance and the costs associated with maintenance and repairs. The permanent removal of defects has proven to be the ultimate and effective solution to avoid late penalties.

The ultimate solution: Removing faults and the adblue injection system

It is possible to deactivate the AdBlue parameters by software using a program specially developed for this. This type of program makes it possible to deactivate the functions linked to AdBlue, such as the injection of emission reduction liquid and the regeneration of the diesel particulate filter (DPF).

To do this, it is necessary to access the parameters of the ECU (Electronic Control Unit) of the vehicle and modify the configuration parameters. This can be done by using a diagnostic tool specially designed to access the parameters of the ECUs. This maintains machine performance without the additional costs of using AdBlue. It is also possible to save on maintenance and repair costs by avoiding problems with the AdBlue system.

It is important to verify that the flashing is performed by competent professionals to avoid material damage or machine performance problems. If flashing is done correctly, it can help keep the machine running smoothly on the jobsite and avoid late penalties.