Cat M313D fault: Gauge, Adblue level and Communication

Persistent faults on the AdBlue CAT M313D system

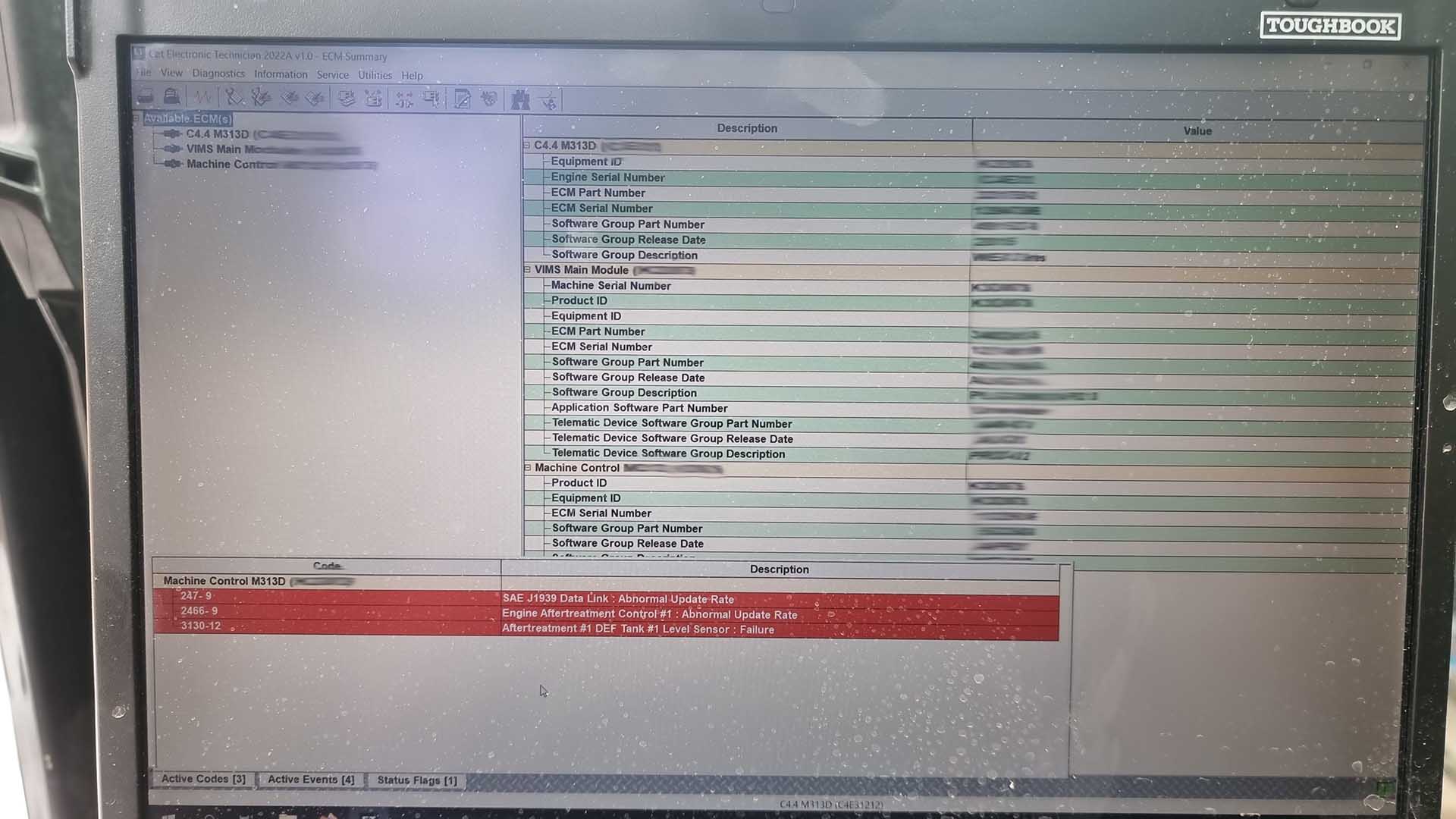

Following a recurring problem on an M313D wheeled excavator, we had to permanently remove the SCR system. Indeed, the post-processing control data are disturbed. The signal does not reach the ADEM V engine control module correctly. Two main faults are present on this excavator: fault 2466-9 and fault 3130-12.

Fault 2466-9 indicates that there is a problem with the Caterpillar M313D wheeled excavator engine aftertreatment management system. “Abnormal update rate” means the system data update rate is abnormal or wrong. This can be caused by a number of factors, such as a problem with system sensors, faulty software, or communication issues.

Fault 3130-12 advises that there is a problem with the Caterpillar M313D wheeled excavator engine exhaust aftertreatment NOx reductant (DEF) tank level sensor. DEF is the acronym for “Diesel Exhaust Fluid”, it is adblue. Its purpose is to reduce NOx emissions. The DEF tank level sensor measures the fluid level in the DEF tank and sends information to the aftertreatment management system. If this sensor is not functioning properly, it can cause performance or reliability issues with the emissions management system.

The complete tank as well as the gauge have been changed by the owner but the fault persists. The ultimate solution is therefore to permanently remove the post-processing system (and resell the machine).

SCR removal on M313D excavator

The shovel being in degraded mode, it was totally impossible to work with. Indeed the limp mode blocks the engine performance at 100% on this shovel, it could not even be moved.

The total and definitive removal of the post-processing system is done using specific software to flash a new engine program developed by our team of engineers. This program defines that the injection of DEF will be zero, permanently erases the fault codes from the dashboard, avoids the consumption of adblue. Plus it skips emission-related engine performance restriction limits. Theoretically it should only be possible to carry out this operation if the excavator was resold abroad because it would no longer correspond to anti-pollution standards. It is the responsibility of the end customer to do with it what he wishes.

We also had fault 247-9 (SAE J1939 Abnormal rate update). This fault 247-9 is related to the other faults mentioned, because the SAE J1939 communication system can be used to transmit data between different systems on the machine, such as the engine management system and the exhaust aftertreatment computer. . Once our new program has been flashed, we can disconnect the post-processing computer without having any faults. The problem is therefore solved. We configure the module not present via our tools.